Characteristics and pain points of cosmetics production enterprises

(1) Poor functionality scalability;

(2) A large number of molds, spare parts storage and management.

(1) Higher level of technical staff is required;

(2) Consuming a lot of time for changeover and commissioning.

(1) Difficulty in expanding production, more labor in multiple shifts;

(2) Smaller workshops in general.

(1) Appearance affects selling price, market complaints.

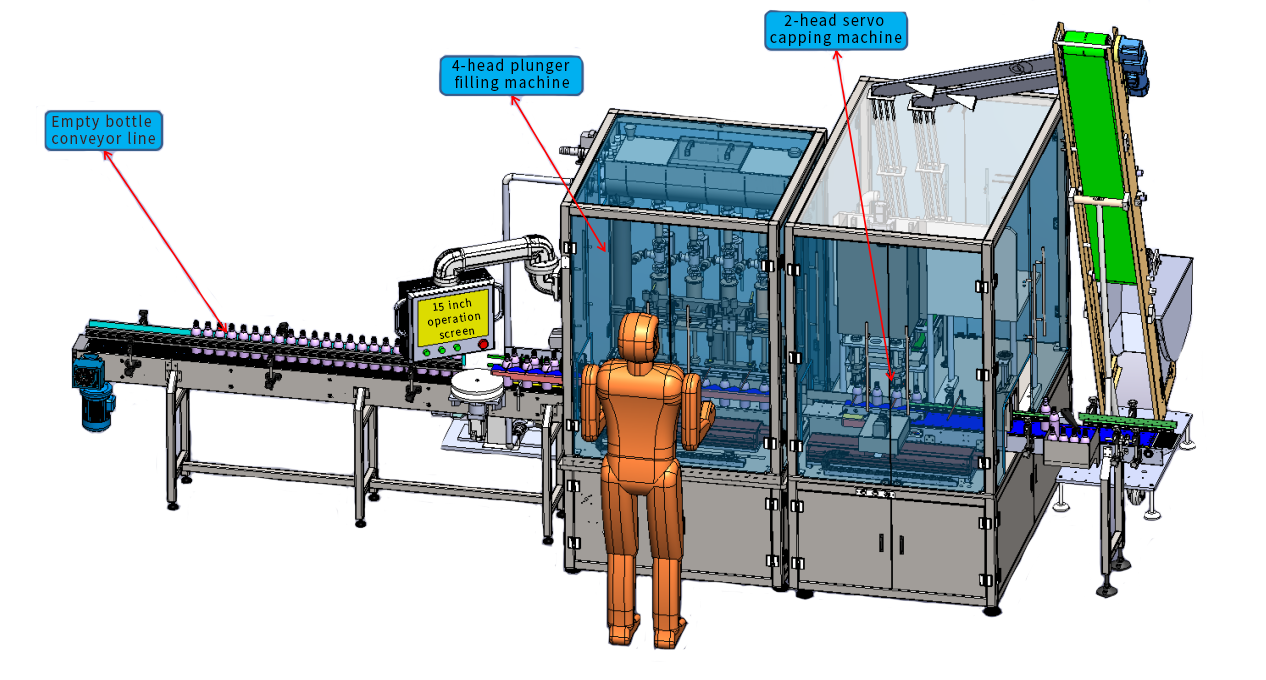

As shown in the picture below, this emulsion filling line consists of empty bottle conveyor, 4-head filling machine, 2-head capping machine, by replacing the plunger pump and toggle clamp can be used for diameter 30-70mm, height 70-220mm, filling volume (30-300g), regular cylindrical bottle filling operation, speed: 60-80 bottles/min.

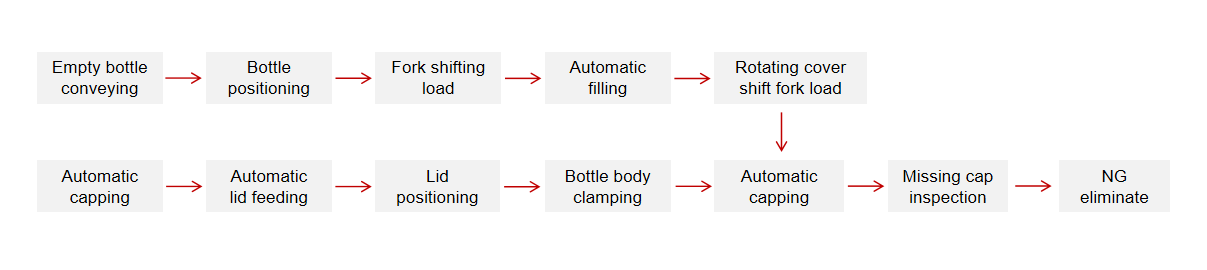

Workflows

Programme features and benefits

Modular flexible design

① For different specifications, switching can be achieved by quickly changing the corresponding fixture;

② Equipment transformation speed convenient, modular design of the filling machine need to speed up only need to add a filling machine and the existing equipment docking, equipment to leave enough control points, electrical wiring using integrated plug, can be quickly connected, the capping machine reserved for an additional set of 2-head capping mechanism of the space, electrical wiring is also using an integrated plug, after the addition of the speed of the equipment can be up to 120 bottles / min;

③ Plunger pump and peristaltic pump mounting bracket using the same mounting method, for different products need to be used in different filling methods, peristaltic pump and plunger pump can be replaced.

Servo controlled filling of piston pumps

① Adopting plunger pump filling, stable filling, high precision +/-1%;

② Four heads filling at the same time, each pump using a separate servo control, can achieve the lack of bottles not to fill;

③ The plunger pump has a quick-insertion design, which allows for quick replacement of the plunger pump for products with different filling volumes.

Servo fork handling

① Bottles are handled with synchronised servo-driven forks for fast speed and high positioning accuracy;

② The toggle clamp is of quick-change design, the toggle clamp has a certain degree of compatibility, for products other than compatible, can be switched by quick-change clamp.

Servo capping mechanism

① Procurement of servo motors with torque feedback to control the capping head for capping, able to provide real-time feedback on the capping torque value.

② Quick-change cap head design, for not using the type of cap, you can quickly change the cap head to achieve the switch.

Servo cap feeding mechanism

① Adopting double-orbit cylinder clamping servo cap feeding method, cap feeding is stable and accurate positioning, avoiding the phenomenon of crooked cap.

② Rapidly adjustable track spacing for quick switching between different lid diameters and heights.