Maximum capacity | |

At the same time WFI+PS maximum capacity | 500L/h+500Kg/h |

WFI Max capacity only | 1000L/h |

PS maximum capacity only | 1100Kg/h |

Allocate system peak usage | 10000L/h |

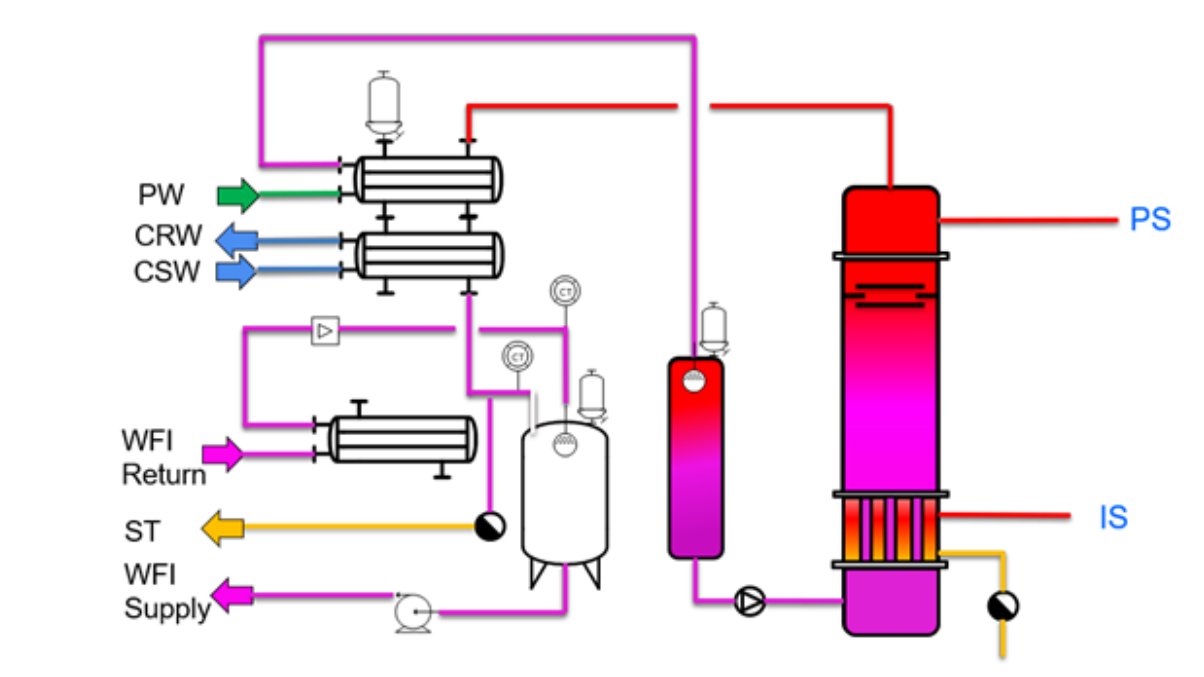

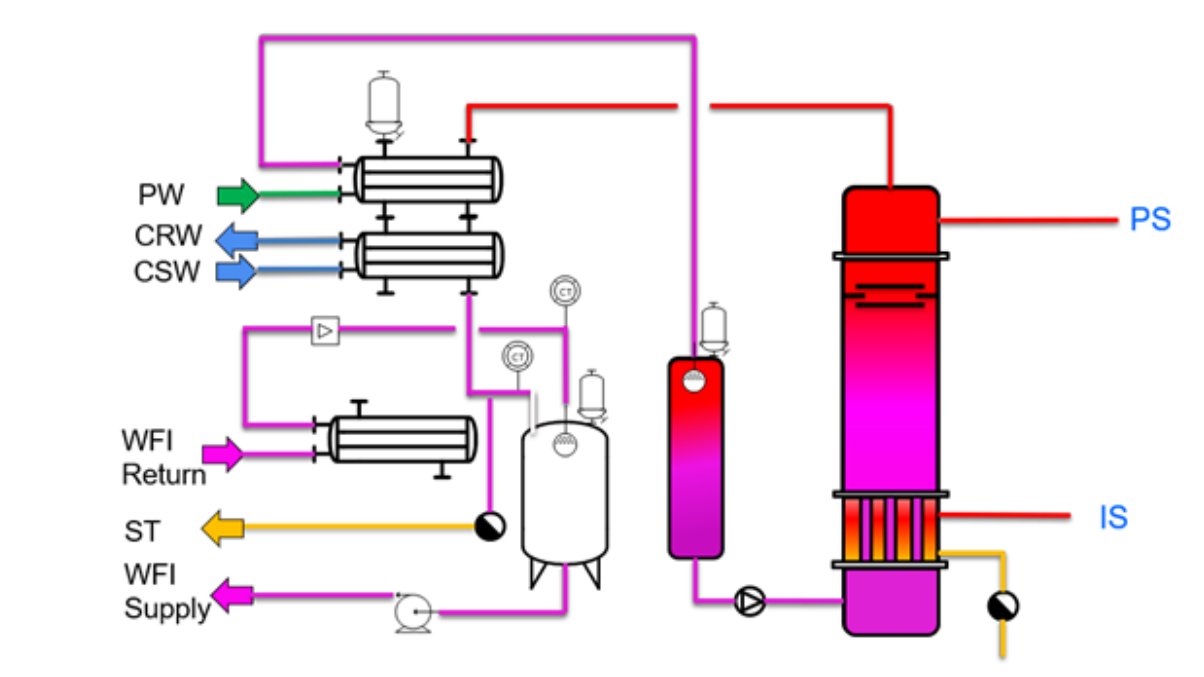

KEYPACK distinctive Three-In-One: Pure steam preparation+WFI preparation+WFl distribution integrated system, specifically developed for small capacity multifunctional systems that handle the common pain points of asset-lite requirements, limited space, and insufficient public media for customers such as laboratories, medical devices, and entrepreneurship parks.

This solution is designed in a modular manner according to GAMP, cGMP, ISPE, and FDA guidelines, allowing for free switching between pure steam and injection water production within the total production capacityrange. In hot standby mode, the vapor positive pressure meets GMP requirements and can be started very quickly. At the same time, the compact structure only requires minimal floor space.

Maximum capacity | |

At the same time WFI+PS maximum capacity | 500L/h+500Kg/h |

WFI Max capacity only | 1000L/h |

PS maximum capacity only | 1100Kg/h |

Allocate system peak usage | 10000L/h |

Project implementation of the full life cycle management, from design selection, program optimization, installation and commissioning, validation support, after-sales maintenance of the whole series of one-stop service.

· CP/USP/EP/JP

· GMP/cGMP

· FDA/CE

· ASME

· GAMP5

· ISPE

· DQ/IQ/OQ/PQ

· RA

· VAT

· FAT

· SAT